Small Entrepreneurs can become Lithium-ion Battery Player in 2025

PR Newswire: A battery pack is a hierarchical and repetitive assembly of individual cells. Lithium-ion batteries are used in many devices and applications, including consumer electronics, electric vehicles, and renewable energy storage. Advancements in battery technology create considerable potential opportunities in the Indian solar battery market. Lithium metal ions have become a popular choice for batteries due to their high energy density and low weight. Millions of people around the world now depend on stairlifts, electric wheelchairs, and mobility scooters.

Business opportunities in lithium-ion battery pack manufacturing

Here's a more detailed breakdown of the opportunities:

- The Indian government has launched the PLI scheme to encourage lithium-ion battery manufacturing in India, offering incentives for companies to establish manufacturing units.

- This scheme aims to create a domestic manufacturing ecosystem for advanced chemistry cells (ACC) batteries, supporting a target of 50 GWh of ACC battery production.

- The demand for lithium-ion batteries is soaring, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems.

- India's National Electric Mobility Mission Plan, along with the government's commitment to renewable energy targets, further fuels this demand.

- The lithium-ion battery market in India is still in its early stages, offering ample opportunity for new players to enter and establish themselves.

- Established players can also expand their presence in the Indian market by leveraging the growing demand and government incentives.

- There are also opportunities in related areas, such as consulting services to improve battery production processes and the development of new battery technologies.

- Recycling plants for end-of-life lithium-ion batteries are another viable business opportunity, addressing environmental concerns and resource recovery.

- India needs to strengthen its lithium-ion battery supply chain, including mineral sourcing, component manufacturing, and recycling infrastructure.

- This presents opportunities for companies to invest in these areas, contributing to a more robust and sustainable battery ecosystem.

In India, electric vehicle (EV) sales in 2024 were dominated by E-two-wheelers, which accounted for about 60% of all sales. The electric three-wheeler (E-3W) market, the second largest segment by volume, also witnessed rapid growth. The cargo segment of E-3Ws performed exceptionally well, experiencing a 45% increase, driven mainly by the growth of logistics and e-commerce sectors and favourable cost benefits.

According to a report by JMK Research and Analytics

In India, most electric two-wheelers utilize lithium-ion batteries with a common voltage of 48V or 72V, and the prevalent battery chemistry is either Lithium Iron Phosphate (LFP) or Nickel Manganese Cobalt (NMC).

- Simple Energy: Simple One - 5kWh lithium-ion (NMC)

- Ola Electric: Ola S1 Pro - varies depending on model, typically lithium-ion (NMC)

- Ather Energy: Ather 450X - lithium-ion (NMC)

- TVS Motor Company: TVS iQube - lithium-ion (NMC)

Most of the 2W and 3W models by leading OEMs come with swappable battery options. Battery swapping is set to gain moreprominence as the re-fuelling method of choice for electric vehicles.

In 2025, most electric three-wheelers in India are likely to use lithium-ion batteries with a chemistry of Lithium Iron Phosphate (LFP), with a typical battery size for a three-wheeler is likely to be around 5 kWh, which provides a decent range for most urban applications.

As of 2025, India is expected to primarily utilize "Advanced Chemistry Cell (ACC)" lithium-ion batteries for swapping, with a focus on larger capacities suitable for electric two-wheelers and three-wheelers, likely ranging between 2kWh to 5kWh per battery pack. Expected to be in the range of 2kWh to 5kWh per swappable battery pack, optimized for smaller electric vehicles like two-wheelers and three-wheelers.

ESS Battery Size Variation:

- Home Systems: Smaller battery packs with capacities ranging from 5kWh to 10kWh for typical household energy needs.

- Commercial Applications: Larger battery packs with capacities in the range of 50kWh to several hundred kWh for businesses and institutions.

- Grid-Scale Storage: Very large battery systems with capacities in the megawatt-hour range for grid stabilization and peak load management.

- Medical devices: Lithium batteries are the preferred choice for many medical devices.

In India by 2025, for solar applications, the most likely lithium-ion battery chemistry will be Lithium Iron Phosphate (LFP) due to its cost-effectiveness and safety features, with sizes varying depending on the application, ranging from smaller capacities for home systems (around 5-10kWh) to larger grid-scale storage systems with capacities reaching several megawatt-hours (MWh) utilizing high-capacity LFP cells.

Lithium-ion batteries power medical devices such as pacemakers, defibrillators, and portable medical equipment due to their reliability and long life.

Lithium-ion batteries have become the preferred power source for drones due to their high energy density and reliability. The Lithium-ion Battery for Drones Market is expected to grow at a CAGR of 6.8% from 2025 to 2033.

Assemble Battery

To start a lithium-ion battery manufacturing business in India, you'll need to secure funding, obtain licenses, and develop a business plan. Lithium iron phosphate batteries can be roughly divided into 12V, 24V, 48V, and high voltage. The 25.6V 120Ah is ideal for ships, electric vehicles, UPS, communication base stations, and other equipment to provide continuous power.

It is recommended that you learn some knowledge about Lithium-ion/LiFePO4 batteries before assembling the battery pack.

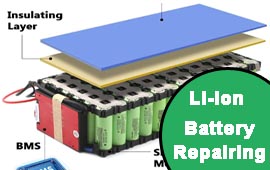

To make a battery with a high quality and reliable warranty, required.

- BMS (Battery Manage System)

- Cells

- Connectors

- Others: EVA sheet - (EVA sheet can be shockproof, fireproof, and insulated), screws, ribbon cables, plastic pipes, (plastic shell has a good insulation performance) etc.

Tool Used:

- Spot Welder

- IR Test

- Spot Welding

- Soldering Iron

- Wire Cutter

- Wire Stripper

- Multimeter

- Charge Discharge capacity tester

If you’re doing a capacity test, be sure to charge the battery until the battery reaches 100%. Then discharge the device until the battery is fully depleted. The discharging test of the battery is very helpful to the battery cycle life and discharge performance evaluation. We can use a professional device(Such as a Programmable DC Electronic Load) to check whether the battery works well or not during the discharging process, which can protect our battery and devices for further daily use.

The Academy of EV Technology (AEVT) Lithium-ion battery pack assembly line course exceeded my expectations! The in-depth knowledge and practical skills I gained have been invaluable in my career which helped me to start my own Lithium Ion battery pack assembly unit in West Bengal. Highly recommend it!Keep inspiring entrepreneurship in West Bengal and all over.

- Sauvik Dasgupta,

Credential ID: AEVTWBHOW220103 in Jan 2022

Behala, Kolkata, West Bengal

Liionergy LLP, Director (Lithium ion battery pack manufacturing unit),

Profile: https://liionergy.in/

Conclusion

India is actively developing its lithium-ion battery manufacturing capabilities, aiming to significantly increase production capacity by 2025. As the industry changes, collaboration between manufacturers, governments and research institutions will be key to overcoming challenges and unlocking the full potential of EVs. With the rise in electric vehicle fires, there is a strong emphasis on battery safety features and testing protocols.

ESS News: Energy storage system development, latest news, press release, analysis and opinion from the global energy storage industry.